Quality management

SB-PEPTIDE is a French company specialized in peptide synthesis and engineering. With more than 10 years producing industrially peptides for worldwide clients, sb-PEPTIDE has faced many situations helping it to orient its objectives around 4 fundamentals to meet client’s satisfaction:

Innovation – Quality – Customer experience – Environment

To reach these objectives the company has developed and is improving every day its Quality Management System to ensure delivering projects with expected specifications.

Production of hundreds very different peptides in same time is highly challenging to manage. Peptides are highly customizable products as many specifications can be variable such as: amino-acid sequence, purity rate, quantity, modifications (about infinite), aliquoting, preferred microtubes, options and other specific requirements… This requires a well designed process with a strong QMS and an continuons staff training. Thanks to several years in managing peptide synthesis projects, SB-PEPTIDE has developed a specific Quality Management System to avoid as best as possible errors and corrective procedures in case an error occurs. Our QMS includes a proprietary and powerful automated documentation system helping generating fabrication orders, registering & tracking data as well as generating certificate of analysis.

The most important remains people all along the process, from sales to shipping through scientists or procurement. Training and internal communication is the key factor to succeed.

Peptide’s quality

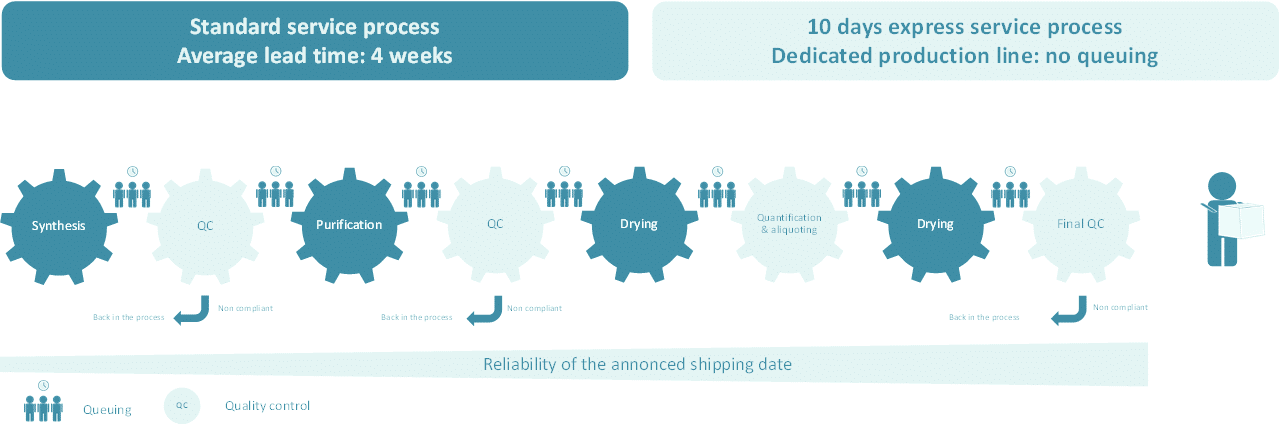

Quality controls allow to characterize peptides properties (purity, identity,…). In-process quality controls are performed at each step (in LC or MS or both) which allows to detect non conformity immediately and go back in the process. Final quality controls are made on final products by a QC laboratory. Synthetic peptides are routinely controled by highest resolutive HPLC, MS, LC/MS systems to assess purity rate and identity, quantified thanks to optimized procedures and visual controls are performed. Many other QCs are available such as salt quantification, NPC determination, sequencing, NMR… (c.f. quality controls and proteomic services)

Simplified general production process

Customer experience

QMS is regulating the entire company including supply chain and sales. Management of client’s requests by sales reprensentatives (quotes, claims, invoices…) is a key component in our client’s satisafaction policy. Our sales representative are peptide specialists and can ensure the best possible understanding of projet specifications, finding technical solutions and translation to the laboratory. Most of technical requests and after-sales support can be handled by sales allowing immediate replies without awaiting for technical service.

Custom synthesis of peptides requires generally several weeks and the exact delivery date can not be given until it passes the final quality control. Assisted by a proprietary predictive tool, SB-PEPTIDE gives for every peptides an estimated lead time taking into account the complexity of the project in order to be as realistic as possible. In case of an anticipated delay, SB-PEPTIDE informs clients promptly to adjust the initial estimated delivery date. SB-PEPTIDE always advise to not schedule experiments with peptides before the project completion. During this several weeks process, the team is always available to provide project’s update. Laboratories and offices, by being in the same building allows rapid exchanges between chemists and sales making feedbacks easy and fast.

Innovation

Innovation allows to offers new solutions or answer specific requests. Being able to answer any requests from clients is a key part of the client satisfaction objectives. SB-PEPTIDE is composed of PhDs in chemistry and has a R&D team dedicated to special projects. It allows to handle complex projects such as long sequences synthesis or develop non existing strategies and rapidly deliver quantities of very specific peptides.

Environment

As a part of the chemical industry and settled in French Alps mountains, SB-PEPTIDE is fully concerned by its impact on environment. The company is doing is best efforts to source raw materials locally to reduce transporation carbon footprint, considers consumption in its chemical strategies and 100% of chemical and consumables wastes are reprocessed by nationally certified organisms. Chemicals are stocked properly to avoid spreading and fires. Facilities are inspected and adapted to avoid any risks to collaborators whom are controlled periodically by medical services.

SB-PEPTIDE is also favorising transportation of staff members using low carbon footprint transportations. The company has settled its facillity in an easily accessible place by public transports (Tramways and buses) and accessible by cycling pathways. SB-PEPTIDE took part financially to public transport of every collaborators and put bicycles at their disposal.